Car Air conditioning System Repair

Before car airconditioning system repair, first is to diagnose the A/C system by checking the pressure and temperature at various locations to determine the problem.

Principles of air cooling of the AC system

The principle that is applied to the automotive air conditioning system is that when a liquid turns into vapor it will absorb heat so that the surrounding area cools down. It is similar to the principle that when a body is wet and the perspiration is exposed to the wind the body will feel cool. (see How does Car AC Work.)

Refrigerant flow

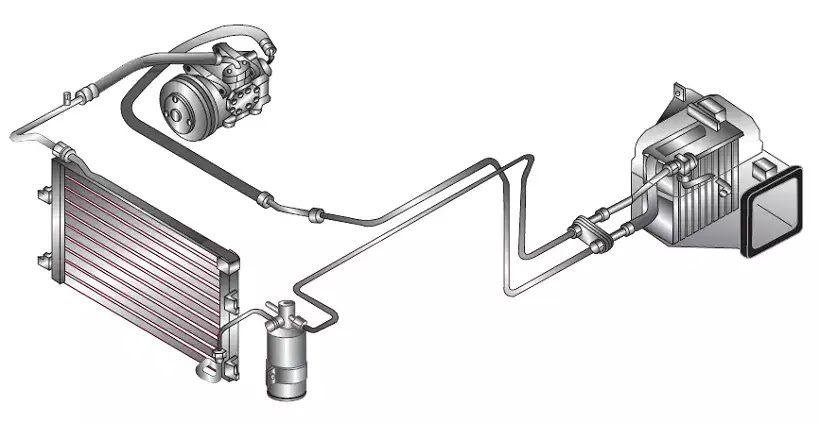

The illustration shows the basic structure of the air conditioning system of an automobile. The cycle is that the refrigerant changes state from the liquid state to the vapor state and back to the liquid state again. The liquid becomes gas when the refrigerant absorbed heat and the surrounding becomes cool, then the gas is compressed making the refrigerant temperature to rise, now as the gas cools down it will return to the liquid state.

Components of Car A/C

Compressor

This component is the one responsible for increasing the pressure and temperature of the refrigerant once the refrigerant evaporates. The compressor serves as the heart of the system.

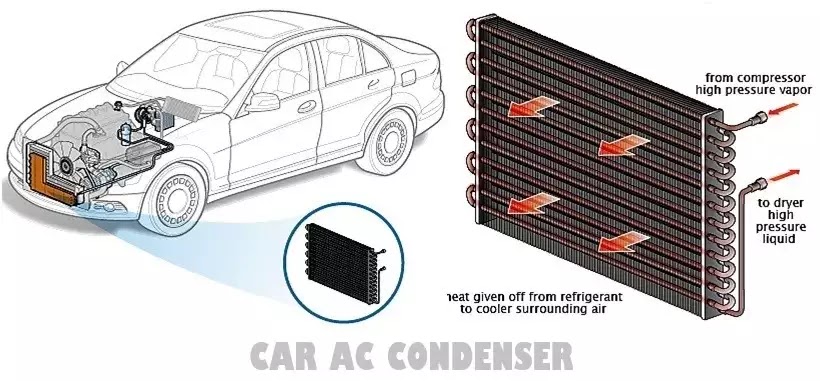

Condenser

The condenser keeps the refrigerant to its liquid state.

Receiver dryer

The receiver dryer is responsible for expanding the refrigerant so that the temperature will go down.

Expansion Valve

The expansion valve is the one that cools down the refrigerant from high temperature and pressure so that the refrigerant will return to the liquid state.

Evaporator

This is where the refrigerant changes state from liquid to gas, as the refrigerant changes state it will absorb heat.

Usage of tools and equipment

1. Moisture and air still exist on the refrigerant line, therefore, evacuation of the system is necessary be done so that the moisture and air will be removed.

2. In connecting the manifold gauge on the A/C system, the blue hose must be connected to the low-pressure side and the red hose is connected to the high-pressure side. The yellow hose is connected to the vacuum pump or charge valve. The manifold gauge can be used for the R12 and R134 air conditioning systems.

3. Used a service valve so that the amount of refrigerant that is discharged to the air is minimal.

4. Weight the amount of refrigerant to charge to the a/c system depending on the car model.

5. Connect the A/C refrigerant pipes and use a torque wrench to tighten the nuts.

Change of pressure and temperature

When there are changes in the pressure and temperature of the refrigerant system it means that there is a malfunction in the system.

Trouble diagnosis for an unusual pressure

When there is an unusual pressure on the high and low sides of the system use a manifold gauge to diagnose the problem. There is a marker above the manifold gauge scale that indicates the standard pressure corresponding to the standard pressure range.

Hi and low side pressure is very high using the manifold gauge

1. The pressure is reduced after water is splash on the condenser, this means that there is an excess refrigerant charge on the system. To correct the problem just reduce the amount of refrigerant on the system until the correct pressure is attained.

2. Air suction by cooling fan is insufficient, the possible cause is that the condenser fins are clogged or the cooling fan rotation is improper. To fix this problem try to clean the condenser or check the cooling fan and repair if necessary.

3. The low-pressure pipe is not cold or when the compressor is stopped the high-pressure value quickly drops at approximately 196 kpa and then gradually decreases thereafter, this means that there is a poor heat exchange in the condenser because of air in the refrigeration cycle. To fix the problem evacuate the system repeatedly and then recharge.

4. The area of the low-pressure pipe is colder than the area near the evaporator outlet or the plates are sometimes covered with frost, this means that there is an excessive liquid refrigerant on the low-pressure side or an excessive refrigerant discharge flow or the expansion valve is opening is small compared to the standard. Usually, the cause of the problem is the improper installation of the expansion valve or improper adjustments of the expansion valve. To fix the problem, the expansion valve should be replaced.

The high-pressure side is too high and the low-pressure side is too low

1. The upper side of the condenser, as well as the high-pressure side, is hot but the liquid tank is not hot, this means that the high-pressure tube or parts located between the compressor and the condenser are clogged or crushed. To fix the problem check for the contamination of the lubricants, also check and repair the malfunction part.

High-pressure Side is Too Low and Low-pressure Side is Too High

1. After the operation of the compressor stops the high pressure and low-pressure side becomes equal, this means that the compressor operation is improper because of damage inside the compressor packings. Just replace the compressor to fix the problem.

Both the high and low-pressure side is too low

1. The outlet temperature is extremely low and there is a big difference in the outlet and inlet of the receiver drier. The liquid tank inlet and expansion valve is frost. This means that the liquid tank inside is slightly clogged. To fix the problem just replace the liquid tank and check the lubricant for contamination.

2. The expansion valve inlet temperature is lower than the temperature near the liquid tank. The expansion valve inlet may be frosted. There is a temperature difference between the high-pressure side. This means that there is clogged on the pipe between the receiver drier and the expansion valve. To fix the problem check the system for lubricant contamination, also check and repair the malfunctioning parts.

The low-pressure side sometimes become negative

1. The AC system does not cool the compartment air. This means that the refrigerant does not discharge or the moisture is frozen on the outlet and inlet of the expansion valve. Also, there is water that is mixed with the refrigerant. To fix the problem, drain the water from the refrigerant or replace the refrigerant. Also, replace the liquid tank.

Watch more videos on auto repair. Subscribe to our Cartechhome Channel on Youtube.

Comments

Post a Comment

Share with us what you think about this topic to help others know more information that this article did not cover.

Kung may tanong po kayo comment lang po, at sasagutin namin sa mga susunod na araw. Marami pong salamat!